MES THINKING

Have you thought about adopting smart technology in your plant?

...but worried about the costs, the expertise/training needed and viability of connecting it to your existing machines?

SMART technology or Industry 4 can seem daunting. It can seem a bit futuristic and high tech.

There are so many types of smart technology that we now use in our daily lives as standard offering us an array of benefits, but they all tend to have some things in common, they:

- Make our lives easier

- Save us time

- Give us the information that we need when we need it

- Are accurate

The examples that we used: The smart home temperature controller means that when we are away from home we can lower the temperature remotely, or when we have guests coming and we need more hot water, we can open the app and in 3 seconds make the necessary adjustments.

Our fitness watches show us what activities burns more calories, how much sleep we have and allows us to see patterns and what we can change to increase fitness, or lower BMI or improve sleep. The handheld scanners means that you don’t have to put your shopping on to the conveyor belt and back into your trolley, saving you time and effort.

It is exactly the same with a smart factory

All that is involved in turning your factory into a smart factory is employing technology to make your job easier, more efficient, more accurate and saving you time and money.

production monitoring dashboard smart technology

But actually, it is no different to what we are all using in our daily lives now. From the smart home temperature controller allowing us to control the temperature of our homes when we are out, to our emails being accessible on our phones, to our fitness watches keeping track of how many steps and how many calories we are burning and showing us how we can do more of some stuff to be healthier.

Many supermarkets now give customers their own handheld scanners so that we can scan our shopping as we shop.

Most of us use Satnav to get to new places now, making driving less stressful and safer than when we used to have to negotiate the roads whilst looking at our huge paper maps. Sat nav technology also warns us of standstill traffic and offers an alternative route

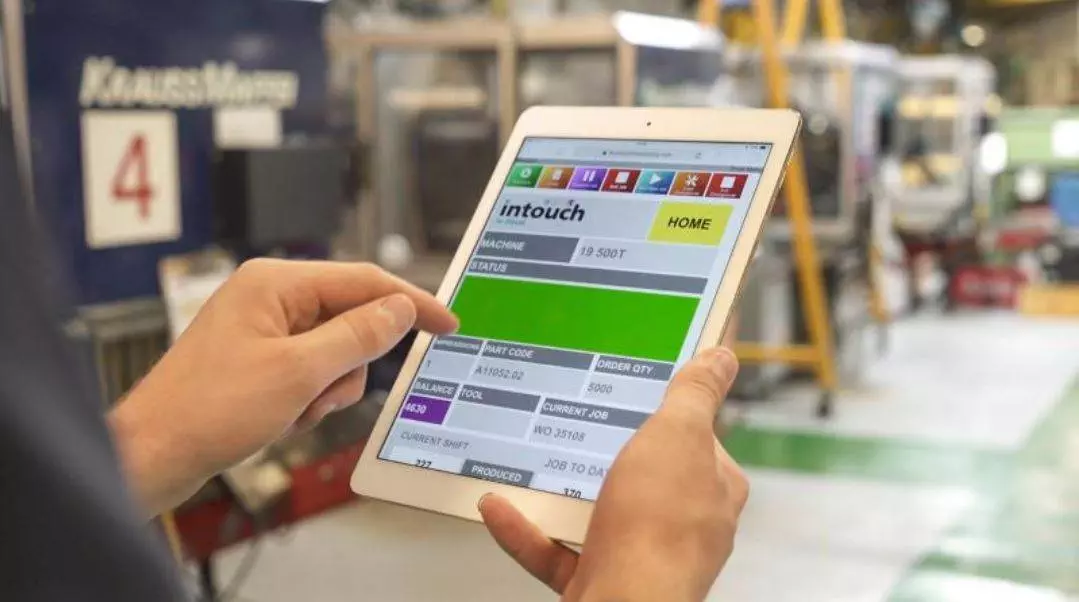

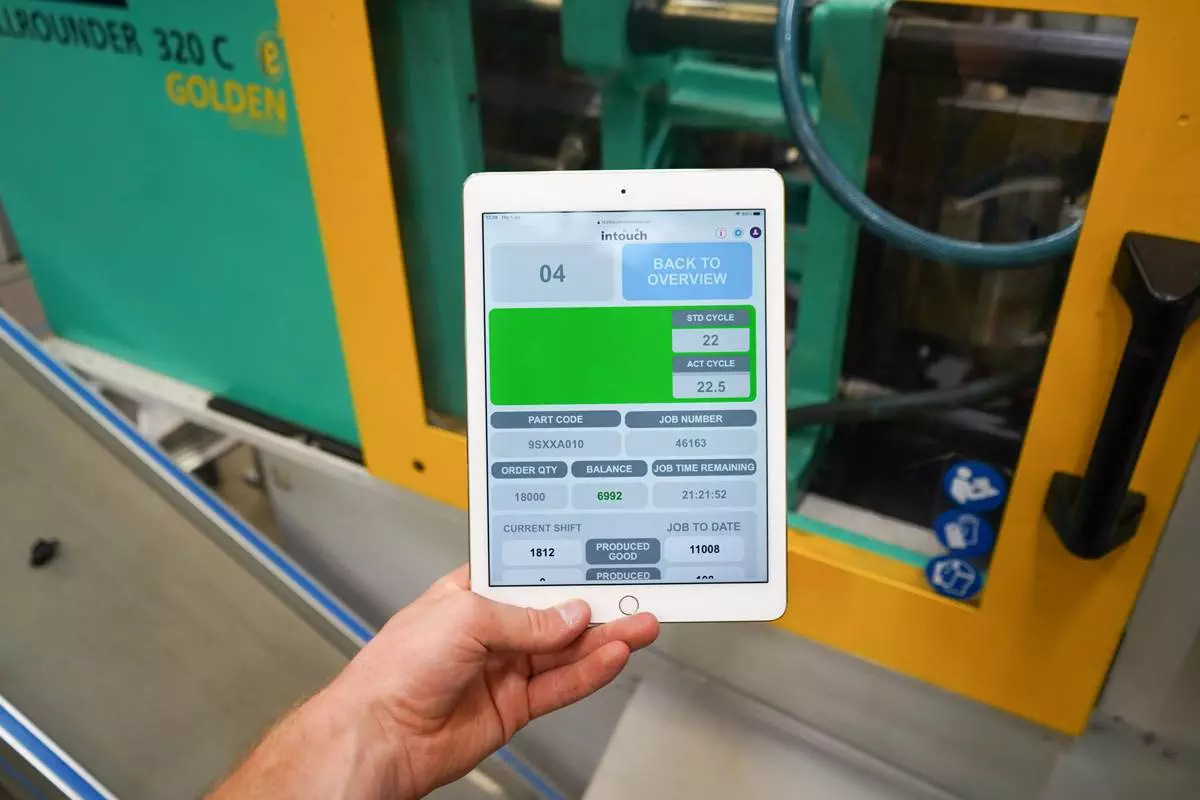

Intouch has spent more than 20 years ensuring that our system gives users the visibility and control to easily make decisions which consistently leads to significant improvements in OEE and profitability.

What about costs – is smart technology expensive?

It used to be that buying a Manufacturing Execution System for example would require a significant upfront investment that would take anything from a year to a few years for ROI. Cloud technology has brought new technology to the reach of anyone with its low monthly subscription and scalable model.

This has also made it possible to offer free trials, giving peace of mind to anyone considering investing in the new technology.

Is smart technology secure?

People don’t trust Cloud technology when it comes to business in a way that doesn’t worry them when they are dealing with personal stuff. Nowadays, everything is on the Cloud. Our banking, our shopping, our photos, our documents. Manufacturing cloud-based technology is no different.

And in the same way that you only trust reputable brands that have been around for a while with your personal things, if you do the same with your business/manufacturing, it will be the same and just as secure because they have a proven track record.

I’m worried that my machines are too old

I have a mix of old and new machines and they have different processes – can I still turn my factory into a Smart factory?

You may think that you need to invest in new machines to benefit from any new technology that you implement, but that isn’t the case. Intouch monitoring, for example, is just as effective when implemented in new and legacy machines and can simultaneously monitor all the different type of process machines in your plant.

Do I really need Industry 4.0?

Well, you can still manufacture without industry 4.0, but the answer is that if you hope to stay competitive or profitable, then YES, YOU ABSOLUTELY NEED IT.

Because your competitors are implementing Industry 4.0 and because of that they are able to manufacture more efficiently, reduce lead times and provide a much better and informed service with consistent quality to their customers.

What about training?

“I can’t afford for my staff to take a long time learning how to use the new technology”

Like with all the technology we are using at home, smart manufacturing technology is designed to be intuitive, so all you need is a little training upfront to learn what you can do with it and then you are ready to go. Intouch staff are always at the other end, happy to help at any time (we have a long-standing reputation for being very helpful).

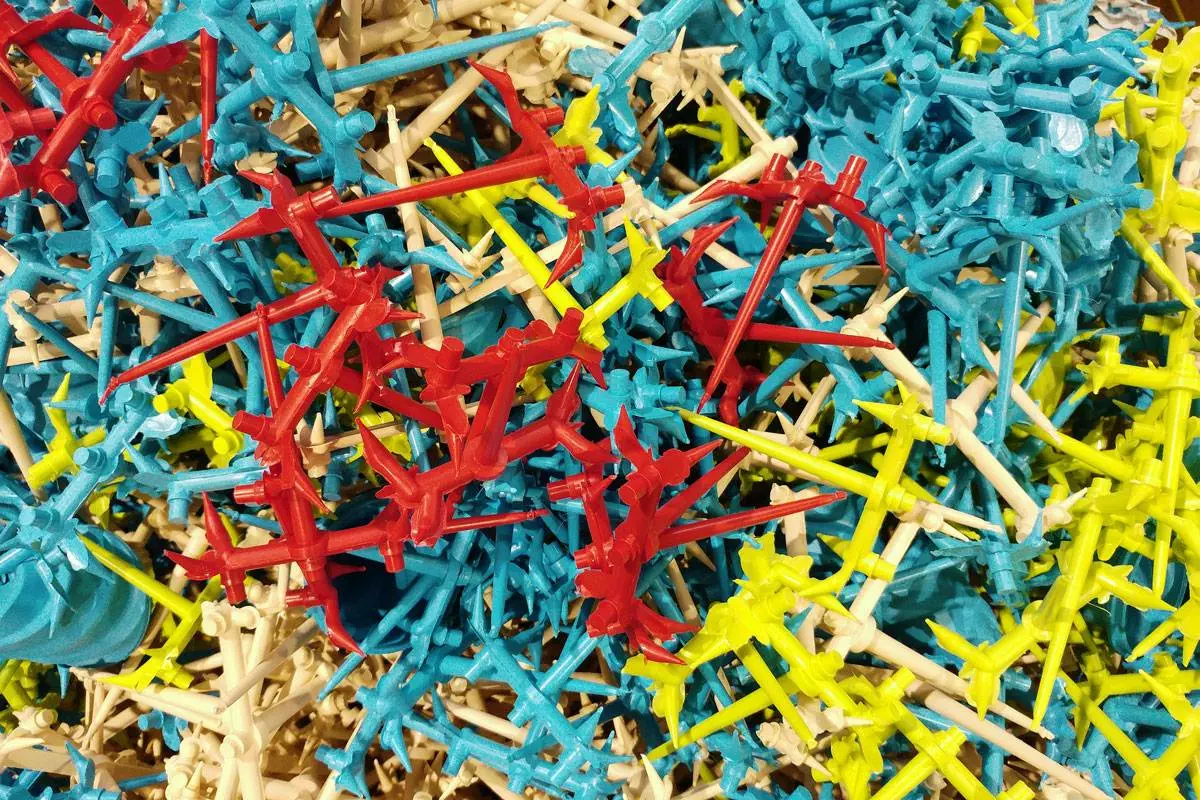

Take your plastics manufacturing to the next level

If you’re experiencing any of the above issues, it’s time to invest in smart technology. Smart technology can help resolve production bottlenecks, keep up with production demands, and reduce costs.

Intouch Monitoring specialises in providing manufacturing solutions that give you complete clarity and control of your operations. With a 60 day free trial, you can have your Intouch system installed and your staff using it in weeks

3 Signs that you are ready to digitise your factory

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

Plastics Manufacturing in a volatile world

The pandemic has highlighted that the need for flexibility and adaptability in manufacturing operations is crucial for navigating…

5 ways you could improve your production efficiency right now

The importance of production efficiency cannot be overstated. It means you are making the most out of your resources – time, materials,…

The advantages of a paperless manufacturing operation

So what happens when you switch to a paperless Manufacturing Execution System? You immediately get more predictable manufacturing with more…

Why is planned downtime for maintenance so important?

Often with pressure of delivery deadlines, it is easy for planned maintenance to be pushed down the priority list and only maintain it when…

How to choose the right manufacturing execution system (MES) for you

Selecting the right MES solution will give you the data and insights necessary to optimise your OEE, give you a competitive advantage and…

What would a 1%, 5% or 30% improvement in OEE mean to you?

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

How to transform your plant’s efficiency and profitability with MES

Squeezing everything from your resources without compromising on quality is a challenge increasingly faced by manufacturers. So how can…

How it works

Getting started with Intouch is as easy as 1, 2, 3

1. Book a demo

Let us show you what we can do. Jump on a demo call and our friendly team will take you through the Intouch system and answer any questions you might have.

2. Enjoy a free trial

Don’t just take our word for it! We’ll lend you our technology for a 60-day free trial so you can see exactly how it can benefit the everyday operation of your business.

3. Receive ongoing support

It doesn’t end there. If you decide Intouch is the right production monitoring system for you, we’ll work with you to help you take control and make significant improvements in OEE.