MES THINKING

OEE and its importance in improving manufacturing performance

Manufacturing businesses invest heavily in their equipment, often at huge capital cost. The lifespan of factory floor machinery can be anything up to 35 years depending on the machine.

In order to ensure the maximum return on those investments (ROI) and that maximum performance is achieved, a well known performance indicator is used i.e. Overall Equipment Effectiveness (OEE).

OEE is a critical metric in manufacturing, crucial for assessing the efficiency and effectiveness of shop floor operations. It serves as a comprehensive gauge of a factory’s operational health, impacting margins and profits directly. Understanding and optimizing OEE is key to improving manufacturing performance.

There are three primary performance indicators, that make up OEE which are availability, performance and quality. OEE is calculated by multiplying these three performance indicators, each playing a pivotal role in the effectiveness of equipment and processes.

The importance of OEE metrics

The three elements of OEE serve as a crucial measure for manufacturing productivity and operational excellence. It provides vital information to leaders and executives for decision-making regarding capacity planning, pricing, and costs.

This together with determining staffing needs, troubleshooting production line issues and scheduling. OEE is made up of three key elements

1. Availability

Availability measures the proportion of time that equipment is available for production against the scheduled time. It is a direct indicator of how well downtime is managed, including breakdowns and maintenance. High availability means equipment is ready when needed, ensuring maximum use of production time. Strategies to improve availability include implementing preventive maintenance and reducing setup times.

2. Performance

Performance is the second element, assesses whether equipment is operating at its maximum speed. This element ensures that production processes are not only running but running efficiently. Factors affecting performance include speed losses and minor stoppages, which can be mitigated by optimizing production rates and streamlining processes.

3. Quality

Quality, the final element, focuses on the output, specifically the proportion of good units produced against the total units started. High-quality production is crucial as it minimizes waste and rework, ensuring more production time is dedicated to creating salable products. Enhancing process control, training employees, and implementing stringent quality checks are ways to improve this metric.

Using OEE to improve performance

Utilising OEE effectively on the shop floor means employing these three metrics to identify and rectify bottlenecks in the production process. By focusing on specific elements, factories can make targeted improvements. For example, enhancing performance can lead to faster production times without compromising quality. More importantly OEE offers objective data for informed decision-making, helping businesses to prioritise investments and improvements.

Improving OEE can significantly impact a factory’s margins and profits. Enhanced efficiency reduces operational costs, as efficient processes consume less energy, require fewer repairs, and waste fewer materials.

A higher OEE score often correlates with increased production output, meaning more products can be sold without a proportional increase in operational costs. Better quality control results in fewer returns and higher customer satisfaction, potentially increasing sales and enhancing the brand’s reputation.

Misunderstandings and misuses of OEE

It’s also important to recognize how OEE can be misunderstood and misused. Misinterpretation of OEE can lead to misguided strategies, which can adversely impact on production efficiency and profitability.

1. Neglecting the balance among all the OEE components: Focusing excessively on one OEE component (such as performance) while neglecting others (like quality or availability) can lead to an unbalanced and inefficient operation. For example, emphasizing speed (performance) at the expense of quality can result in higher output but also in increased waste and rework.

2. Using OEE as a comparative metric across different operations: OEE is most effective when used to measure and improve a specific operation over time. Comparing OEE scores across different machines, lines, or plants without considering the context and differences in operations can be misleading.

3. Misinterpreting OEE for individual performance metrics: OEE is designed to measure equipment effectiveness, not individual worker performance

4. Ignoring external factors: Externally driven fluctuations, such as changes in demand, supply chain issues, or market conditions, can affect OEE. Failing to consider these factors when evaluating OEE can lead to incorrect assumptions about production efficiency and effectiveness.

5. Data quality: The accuracy of OEE is heavily dependent on the quality of data collected. Poor data collection methods, errors in data entry, or manipulation of data to present a favourable OEE score can lead to misinformed decisions and strategies.

Role of Production Monitoring to improve OEE and improve performance

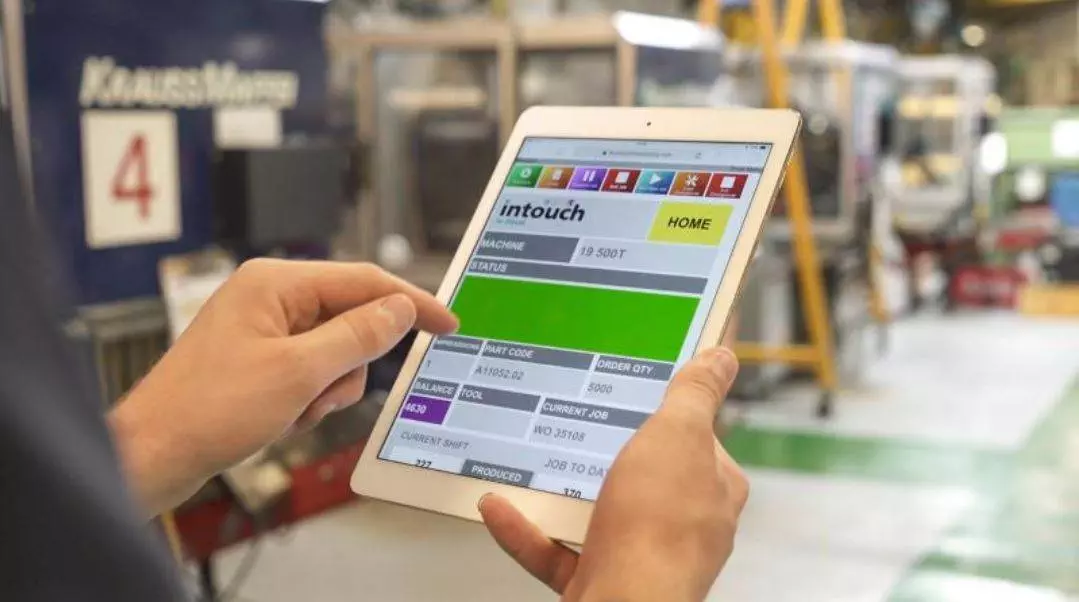

When businesses are looking at using OEE to improve performance, it’s important to consider the role production monitoring plays in enhancing these metrics. Production monitoring provides a digital method for tracking and analyzing the performance of manufacturing operations and machines in real time and plays a pivotal role in improving OEE.

Production monitoring contributes to each element of OEE—Availability, Performance, and Quality in distinct ways:

Enhancing availability through real-time data

Production monitoring systems provide real-time data on equipment status, allowing for immediate identification of downtime issues. By monitoring equipment performance continuously, manufacturers can quickly identify and address unplanned downtimes or maintenance needs, thereby increasing the availability of machinery.

Optimizing performance with detailed Insights

These systems offer detailed insights into production speed and process efficiency. By analyzing data from production monitoring systems, manufacturers can identify patterns and trends that lead to performance losses, such as recurring minor stoppages or inefficiencies in production sequences.

This information enables targeted interventions to improve the overall performance rate of the equipment.

Improving quality through early detection

Quality control is significantly enhanced by production monitoring. These systems can detect deviations in product quality at an early stage, allowing for immediate corrective actions. This early detection helps minimises waste and ensures a higher proportion of products meet quality standards.

Planned maintenance and reduced downtime

With advanced monitoring technologies, factories can shift from reactive to predictive maintenance strategies.

By predicting equipment failures before they occur, production monitoring can significantly reduce unplanned downtime, directly improving the Availability component of OEE.

Improving performance with OEE

A focus on OEE is essential for the success of any manufacturing operation. Understanding and improving each component of OEE allows factories to operate more efficiently, reduce costs, increase output, and boost profitability. This holistic approach ensures every aspect of the production process positively contributes to the bottom line, making OEE a cornerstone of modern manufacturing strategy.

Production Monitoring plays a pivotal role in enhancing OEE on the shop floor. By providing real-time data and insights, it enables manufacturers to proactively manage their equipment and processes, leading to improved availability, performance, and quality.

Would you like to learn more?

If you’d like to learn more about how you can implement production monitoring software, talk to one of our experts:

3 Signs that you are ready to digitise your factory

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

Plastics Manufacturing in a volatile world

The pandemic has highlighted that the need for flexibility and adaptability in manufacturing operations is crucial for navigating…

5 ways you could improve your production efficiency right now

The importance of production efficiency cannot be overstated. It means you are making the most out of your resources – time, materials,…

Have you thought about adopting smart technology?

What's stopping you adopting smart technology in your plant? Are you worried about the costs, the expertise and training needed? What is…

The advantages of a paperless manufacturing operation

So what happens when you switch to a paperless Manufacturing Execution System? You immediately get more predictable manufacturing with more…

Why is planned downtime for maintenance so important?

Often with pressure of delivery deadlines, it is easy for planned maintenance to be pushed down the priority list and only maintain it when…

How to choose the right manufacturing execution system (MES) for you

Selecting the right MES solution will give you the data and insights necessary to optimise your OEE, give you a competitive advantage and…

What would a 1%, 5% or 30% improvement in OEE mean to you?

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

How to transform your plant’s efficiency and profitability with MES

Squeezing everything from your resources without compromising on quality is a challenge increasingly faced by manufacturers. So how can…

How it works

Getting started with Intouch is as easy as 1, 2, 3

1. Book a demo

Let us show you what we can do. Jump on a demo call and our friendly team will take you through the Intouch system and answer any questions you might have.

2. Enjoy a free trial

Don’t just take our word for it! We’ll lend you our technology for a 60-day free trial so you can see exactly how it can benefit the everyday operation of your business.

3. Receive ongoing support

It doesn’t end there. If you decide Intouch is the right production monitoring system for you, we’ll work with you to help you take control and make significant improvements in OEE.