MES THINKING

Improving processes for Plastic Molding Manufacturers in the United States

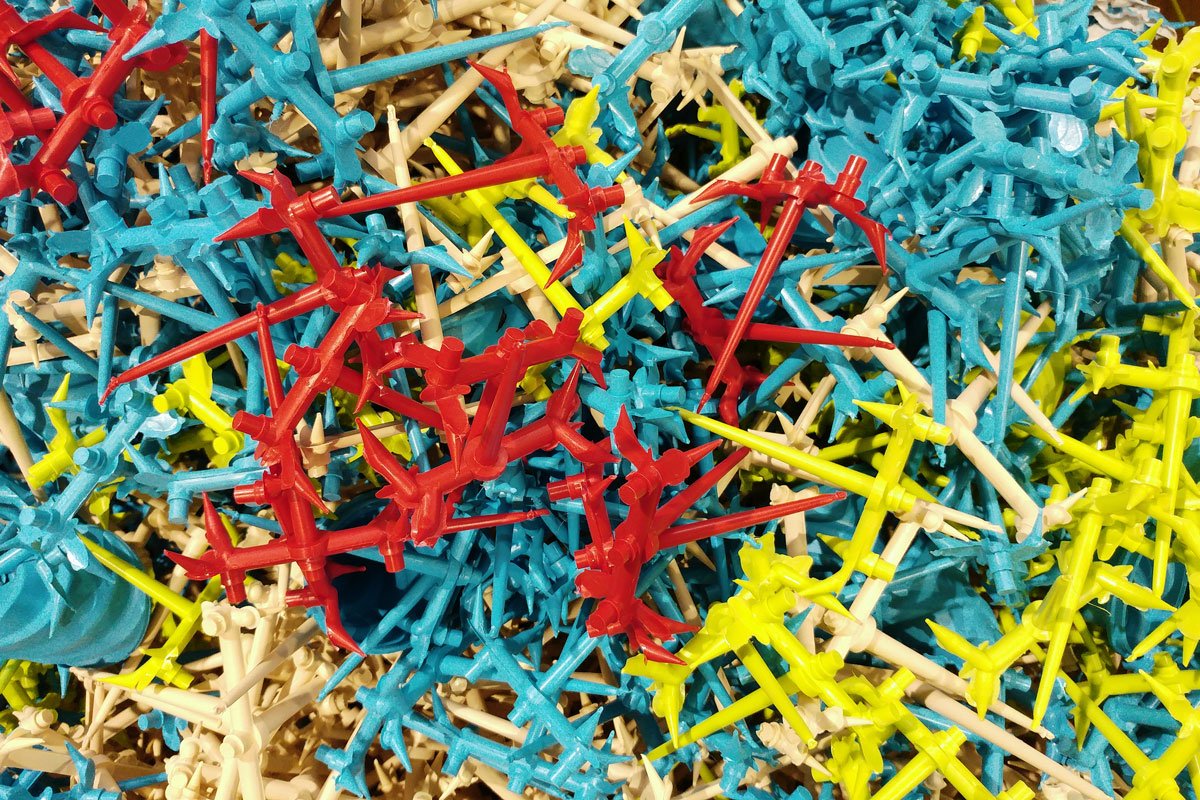

Plastic Molding manufacturing plays a vital role in various industries across the United States, from automotive to consumer electronics.

In an era marked by increasing costs and increasing competition, it is crucial for plastic molding manufacturers to continuously improve processes, improve efficiency and improve margins.

Here we explore the strategies and tactics that aid Plastic Molding manufacturers to improve efficiencies.

1. Adopt lean manufacturing principles

Implementing overarching lean manufacturing principles can significantly improve the overall efficiency of plastic molding operations. Lean techniques aim to reduce waste, optimize production, and streamline processes. Manufacturers can benefit from practices like value stream mapping, production workflow management tools, and just-in-time inventory management to minimize downtime and enhance productivity.

2. Quality control, monitoring, and scrap reduction

Implementing advanced quality control and monitoring systems is essential for maintaining high product standards. Incorporating real-time monitoring can help reduce downtime, detect defects early in the production process, reducing waste and rework.

3. Improving energy efficiency and reducing energy costs

Energy consumption is a significant cost factor for plastic molding manufacturers – idle machines continue to consume energy. The two biggest culprits of energy waste in manufacturing processes are:

· Machines left running when operations have finished

· Equipment faults causing suboptimal performance

Real time energy monitoring can significantly aid in the reduction of energy costs.

4. Innovative and advanced materials

The choice of materials is a critical factor in plastic molding. Manufacturers should stay updated with the latest advancements in materials science to select cost-effective options.

Bioplastics, recycled materials, and lightweight composites are gaining traction as sustainable alternatives to more traditional plastics.

5. Automation tools

Automation is transforming the plastic molding industry. Integrating automated systems for tasks like injection molding, quality control, and packaging can significantly boost production rates and reduce labor costs.

Robotic arms can also perform intricate and repetitive tasks with high precision, ensuring product consistency.

6. Employee Training and Development

Investing in the training and development of employees is essential for achieving process improvements.

Skilled and motivated personnel can identify opportunities for optimization, troubleshoot issues, and equipped with the right technology to support them, your tech and talent will contribute to a culture of continuous improvement.

Improving Processes - Production Monitoring software: Enhancing efficiency and decision-making

Staying competitive requires real-time insights and data-driven decision-making and Production Monitoring software has emerged as a game-changer in improving efficiency by providing manufacturers with valuable information about their processes.

And one myth we can ‘bust’ right now is that whatever the age of you machines, Production Monitoring can be implemented. Here’s how the use of production monitoring software can significantly benefit plastic molding manufacturers in the United States:

Real-time visibility

Production monitoring software offers real-time visibility into every aspect of the manufacturing process. It collects data on machine performance, cycle times, material consumption, and more.

This visibility allows manufacturers to identify bottlenecks, downtime causes, and inefficiencies as they happen, enabling swift corrective actions.

Data analytics

The software analyzes collected data to provide valuable insights and trends. With the help of analytics from the data collected, manufacturers can identify patterns, anomalies, and areas for improvement.

This data-driven approach helps in making informed decisions to optimize production processes.

Predictive maintenance

One of the significant advantages of production monitoring software is its ability to predict maintenance needs. By continuously monitoring machine conditions and performance, the software can anticipate when equipment is likely to fail or require maintenance.

This predictive maintenance minimizes unplanned downtime and extends the lifespan of machinery.

Quality assurance

Ensuring product quality is paramount in plastic molding. Production monitoring software can integrate quality control checkpoints throughout the manufacturing process.

It can flag deviations from quality standards in real-time, allowing immediate adjustments to prevent the production of defective parts and reduce waste.

Process optimization

By analyzing historical data, production monitoring software can help identify areas where processes can be optimized.

This may involve adjusting machine parameters, altering production schedules, or modifying material usage to reduce costs and improve overall efficiency.

Remote Monitoring

In today’s interconnected world, remote monitoring capabilities are essential.

Production monitoring software can be accessed from anywhere, allowing manufacturers to oversee operations and make decisions even when off-site. This flexibility improves responsiveness and decision-making.

The future is bright for Plastic Molding manufacturers in the US

By embracing some or all of the tactics highlighted above, plastic molding manufacturers can enhance their efficiency, reduce costs, and improved competitive advantage.

The adoption of production monitoring software is a key component of improving efficiency and success.

This technology empowers manufacturers to make significant improvements to their processes and efficiencies, and improve their OEE.

Would you like to learn more?

If you’d like to learn more about how you can go paperless and unlock your talent, talk to one of our experts:

3 Signs that you are ready to digitise your factory

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

Plastics Manufacturing in a volatile world

The pandemic has highlighted that the need for flexibility and adaptability in manufacturing operations is crucial for navigating…

5 ways you could improve your production efficiency right now

The importance of production efficiency cannot be overstated. It means you are making the most out of your resources – time, materials,…

Have you thought about adopting smart technology?

What's stopping you adopting smart technology in your plant? Are you worried about the costs, the expertise and training needed? What is…

The advantages of a paperless manufacturing operation

So what happens when you switch to a paperless Manufacturing Execution System? You immediately get more predictable manufacturing with more…

Why is planned downtime for maintenance so important?

Often with pressure of delivery deadlines, it is easy for planned maintenance to be pushed down the priority list and only maintain it when…

How to choose the right manufacturing execution system (MES) for you

Selecting the right MES solution will give you the data and insights necessary to optimise your OEE, give you a competitive advantage and…

What would a 1%, 5% or 30% improvement in OEE mean to you?

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

How to transform your plant’s efficiency and profitability with MES

Squeezing everything from your resources without compromising on quality is a challenge increasingly faced by manufacturers. So how can…

How it works

Getting started with Intouch is as easy as 1, 2, 3

1. Book a demo

Let us show you what we can do. Jump on a demo call and our friendly team will take you through the Intouch system and answer any questions you might have.

2. Enjoy a free trial

Don’t just take our word for it! We’ll lend you our technology for a 60-day free trial so you can see exactly how it can benefit the everyday operation of your business.

3. Receive ongoing support

It doesn’t end there. If you decide Intouch is the right production monitoring system for you, we’ll work with you to help you take control and make significant improvements in OEE.