MES THINKING

The advantages of a paperless manufacturing operation

So what happens when you switch to a paperless Manufacturing Execution System? You immediately get more predictable manufacturing with more consistent quality and less scrap.

Think of all the data that needs to be captured continually in any given manufacturing plant…

And consider that many plants are still operating with paper – every job, every machine… a job sheet for every production order; the setters with their bits of paper with their changeover times listed; scrap and downtime noted at some point.

Any time there is a change, it has to be noted, printed out and distributed… which makes it out of date before the information can be used.

Not only is that a huge job requiring a lot of time (using expensive overheads like labour and paper) but it is invariably inaccurate and always late. Even if records are nearly accurate, that ‘nearly’ can cost the company a lot of time, money and labour.

And then you don’t have the information in a format that can be seen as a whole or broken down to see what you need to change. That means that mistakes will just keep being repeated.

Quality is also affected. It is almost impossible to access and collate manually and on paper, all the information needed about machines, operators and procedures to prevent any errors occurring at every step of the operation. The random checks that tend to take place at paper-based plants to try and prevent errors are largely ineffective.

Intouch has spent more than 20 years ensuring that our system gives users the visibility and control to easily make decisions which consistently lead to significant improvements in OEE and profitability.

So what happens when you switch to paperless Manufacturing Execution Sytem?

You immediately get more predictable manufacturing with more consistent quality and less scrap.

Why?

Real-time monitoring with digital dashboards depicting the factory floor, machines and processes live, means that any issues can be dealt with immediately and before they become a costly problem.

Delivery promises can be consistently met as little production time is lost when correcting errors.

The high visibility of the shop-floor encourages operators to keep production going as well as possible.

All production and process data that has been digitally collected is automatically and accurately recorded in the archive database and made available to the Intouch reporting and analytics modules.

Reports can be configured for any selected time-period and available by machine, tool, product, workgroup or operator with many key performance figures (KPI) such as OEE, scrap, downtime and other defined parameters.

These reports give you a complete overview of what has happened in a variety of graphical ways – from charts to dials, which make anomalies or patterns easy to spot and changes that need to be made become obvious.

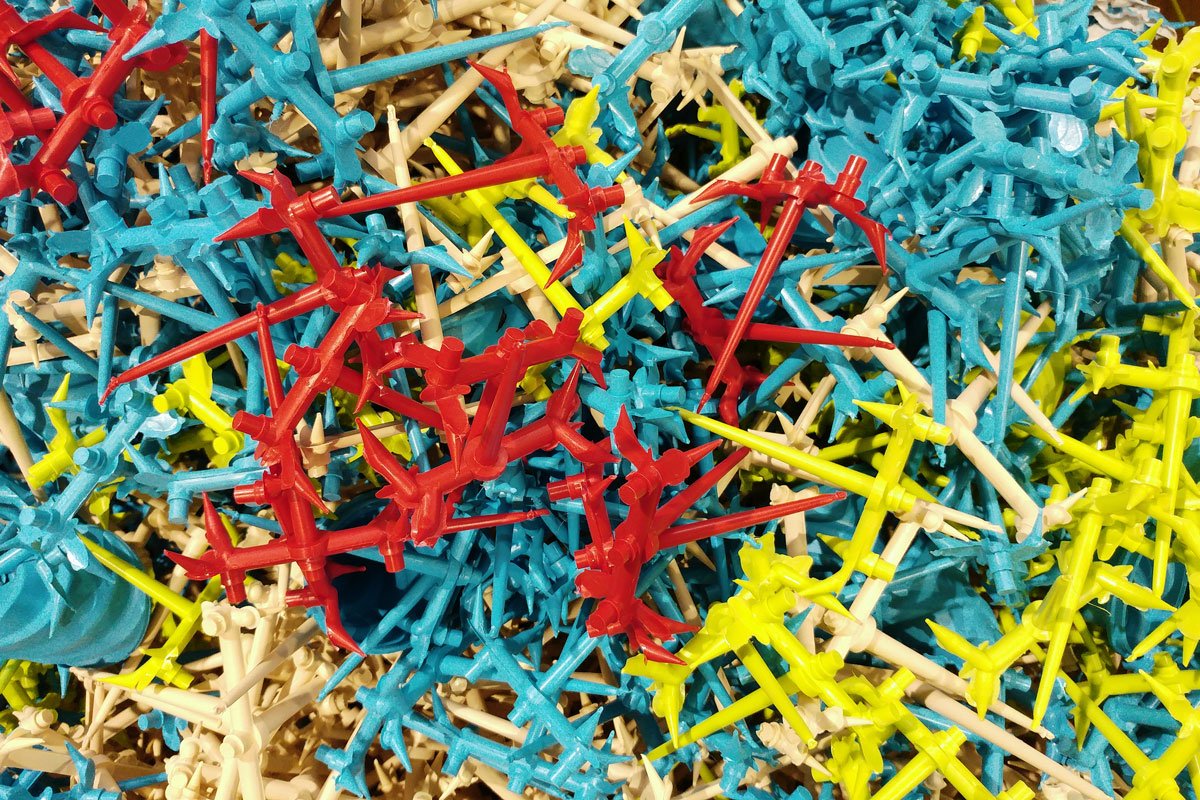

Take your plastics manufacturing to the next level

If you’re experiencing any of the above issues, it’s time to invest in smart technology.

Smart technology can help resolve production bottlenecks, keep up with production demands, and reduce costs.

If you’d like help digitising your manufacturing operations or assistance in improving efficiency and productivity, please get in touch.

3 Signs that you are ready to digitise your factory

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

Plastics Manufacturing in a volatile world

The pandemic has highlighted that the need for flexibility and adaptability in manufacturing operations is crucial for navigating…

5 ways you could improve your production efficiency right now

The importance of production efficiency cannot be overstated. It means you are making the most out of your resources – time, materials,…

Have you thought about adopting smart technology?

What's stopping you adopting smart technology in your plant? Are you worried about the costs, the expertise and training needed? What is…

Why is planned downtime for maintenance so important?

Often with pressure of delivery deadlines, it is easy for planned maintenance to be pushed down the priority list and only maintain it when…

How to choose the right manufacturing execution system (MES) for you

Selecting the right MES solution will give you the data and insights necessary to optimise your OEE, give you a competitive advantage and…

What would a 1%, 5% or 30% improvement in OEE mean to you?

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

How to transform your plant’s efficiency and profitability with MES

Squeezing everything from your resources without compromising on quality is a challenge increasingly faced by manufacturers. So how can…

How it works

Getting started with Intouch is as easy as 1, 2, 3

1. Book a demo

Let us show you what we can do. Jump on a demo call and our friendly team will take you through the Intouch system and answer any questions you might have.

2. Enjoy a free trial

Don’t just take our word for it! We’ll lend you our technology for a 60-day free trial so you can see exactly how it can benefit the everyday operation of your business.

3. Receive ongoing support

It doesn’t end there. If you decide Intouch is the right production monitoring system for you, we’ll work with you to help you take control and make significant improvements in OEE.