MES THINKING

How a manufacturing execution system can transform your plant’s efficiency and profitability

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology in your plastics manufacturing business?

In manufacturing, profit is reliant on how efficient the shop floor is. Squeezing everything from your resources without compromising on quality is a challenge increasingly faced by manufacturers. So how can manufacturers stay competitive whilst maintaining or increasing profit?

Continuous improvement is key. Looking at existing processes and finding ways of making these more efficient and cost effective ultimately leads to a more profitable business. Without a mechanism that collects accurate data and standardises current systems, continuous improvement is often reactionary, where problems are only dealt with after they have become costly and problematic.

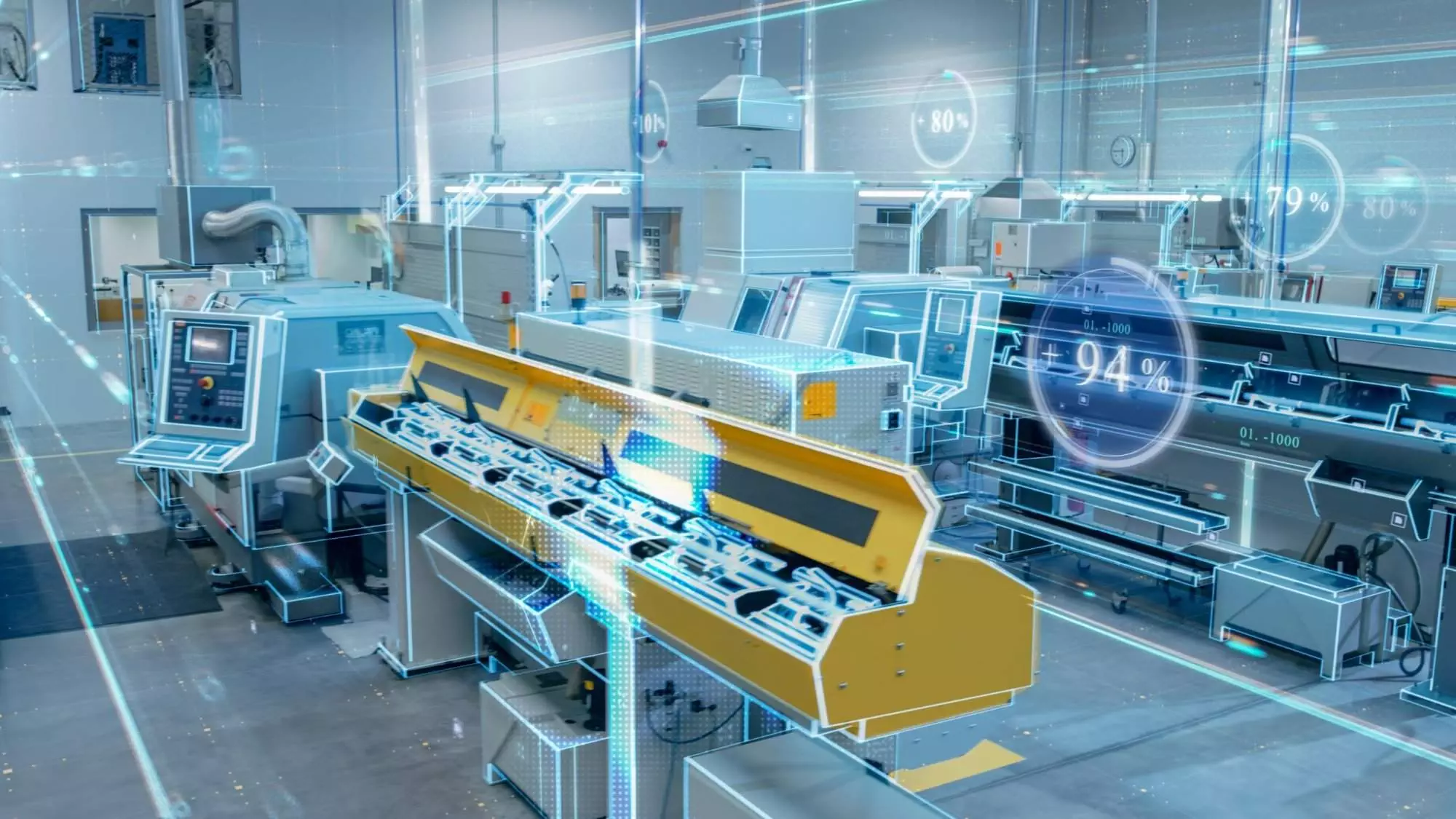

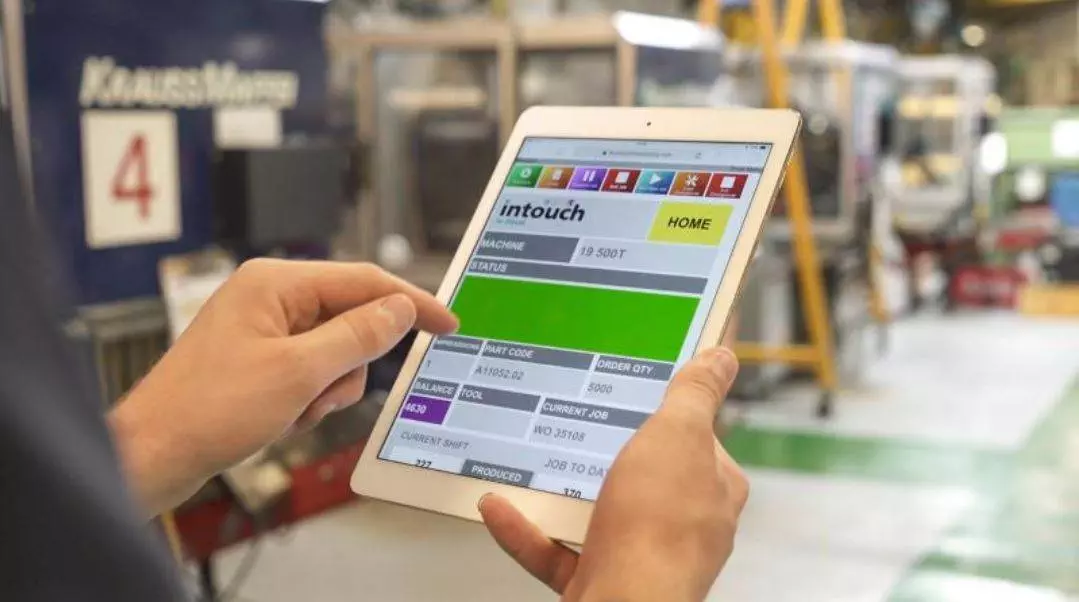

Making sure that you make optimum use of your resources by installing a Manufacturing Execution System (MES) is a quick, easy and cost effective way. Using Intouch Monitoring as an example, real-time scheduling, monitoring and reporting systems gives manufacturers the visibility to easily make continuous improvement decisions that can contribute to improving Overall Equipment Effectiveness (OEE); improving productivity; reducing lead time and production errors; and raising quality.

Intouch has spent more than 20 years ensuring that our system gives users the visibility and control to easily make decisions which consistently lead to significant improvements in OEE and profitability.

1. Production bottlenecks could be a sign you are ready to digitise your factory:

A bottleneck in a sequence of processes reduces the capacity of the whole chain. Any situation on a factory floor that diminishes productivity is a bottleneck that can cause lost revenue and reduced margin, plus many other impacts too.

Bottlenecks can happen due to any number of reasons:

- equipment issues

- staff issues

- late orders

- inefficient planning

- supply chain issues

- late delivery of raw components

So often this is due to not having a clear overview of your production and the ability to quickly and efficiently make changes.

A lack of visibility on what tasks are taking place at any given time can lead you into solving one problem only for another issue arise later.

How can digitising your factory help reduce bottlenecks?

- Scheduling equipment maintenance at the best time to minimise production disruption

- Monitoring your production lines with downtime alerts means you can respond and fix the problem and keep production running smoothly

- Digitising your schedule so that jobs are fitted in to maximise capacity

- Ability to add last minute orders and rearranging schedule so that all orders are produced in time

- Reports and analytics that highlight any issues so you can make the changes necessary to make production more efficient and avoid bottlenecks

- 24/7 visibility from any device

Monitoring

Being able to monitor production in real-time and having live and up-to-date information in any part of your factory removes the costs and errors of collecting production data manually. This enables your personnel to use their time more efficiently and the high visibility also motivates production staff to keep machines operational.

Scheduling/Planning

By using a live scheduling module that shows the progress of every job in the plan operators can get a graphical visualisation of machine loading and capacity utilisation.

Jobs can be highlighted for many reasons, such as tool changes, late jobs or resource clashes and takes shift pattern, planned maintenance, overtime and shutdowns into account. Better planning significantly reduces changeover time and the job schedule view gives details of each job enabling operators to prepare for up-coming tool changes.

Reporting

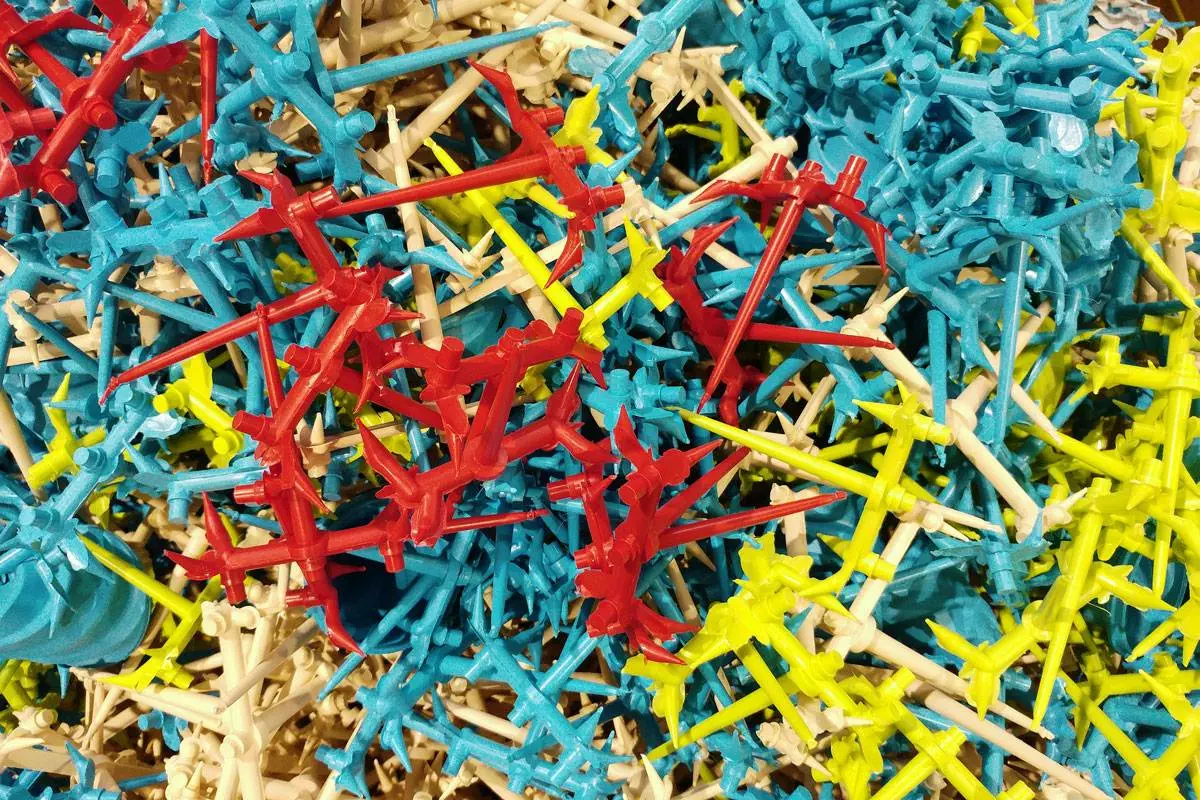

By storing collected data, businesses are able to better track actual materials used and have increased accountability of material use to individual operators, which generally reduces waste. The data enables informed decisions to be made to streamline operations and monitor key processes to better control final product quality and achieve a “zero defect” policy.

Take your plastics manufacturing to the next level

If you’re experiencing any of the above issues, it’s time to invest in smart technology. Smart technology can help resolve production bottlenecks, keep up with production demands, and reduce costs.

If you’d like help digitising your manufacturing operations or assistance in improving efficiency and productivity, please get in touch.

3 Signs that you are ready to digitise your factory

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

Plastics Manufacturing in a volatile world

The pandemic has highlighted that the need for flexibility and adaptability in manufacturing operations is crucial for navigating…

5 ways you could improve your production efficiency right now

The importance of production efficiency cannot be overstated. It means you are making the most out of your resources – time, materials,…

Have you thought about adopting smart technology?

What's stopping you adopting smart technology in your plant? Are you worried about the costs, the expertise and training needed? What is…

The advantages of a paperless manufacturing operation

So what happens when you switch to a paperless Manufacturing Execution System? You immediately get more predictable manufacturing with more…

Why is planned downtime for maintenance so important?

Often with pressure of delivery deadlines, it is easy for planned maintenance to be pushed down the priority list and only maintain it when…

How to choose the right manufacturing execution system (MES) for you

Selecting the right MES solution will give you the data and insights necessary to optimise your OEE, give you a competitive advantage and…

What would a 1%, 5% or 30% improvement in OEE mean to you?

Are you under pressure to improve efficiencies and reduce down time, which means you’re now looking to implement smart factory technology…

How it works

Getting started with Intouch is as easy as 1, 2, 3

1. Book a demo

Let us show you what we can do. Jump on a demo call and our friendly team will take you through the Intouch system and answer any questions you might have.

2. Enjoy a free trial

Don’t just take our word for it! We’ll lend you our technology for a 60-day free trial so you can see exactly how it can benefit the everyday operation of your business.

3. Receive ongoing support

It doesn’t end there. If you decide Intouch is the right production monitoring system for you, we’ll work with you to help you take control and make significant improvements in OEE.