Intouch Monitoring launches new real-time energy waste alert and energy monitoring module.

24th January 2023

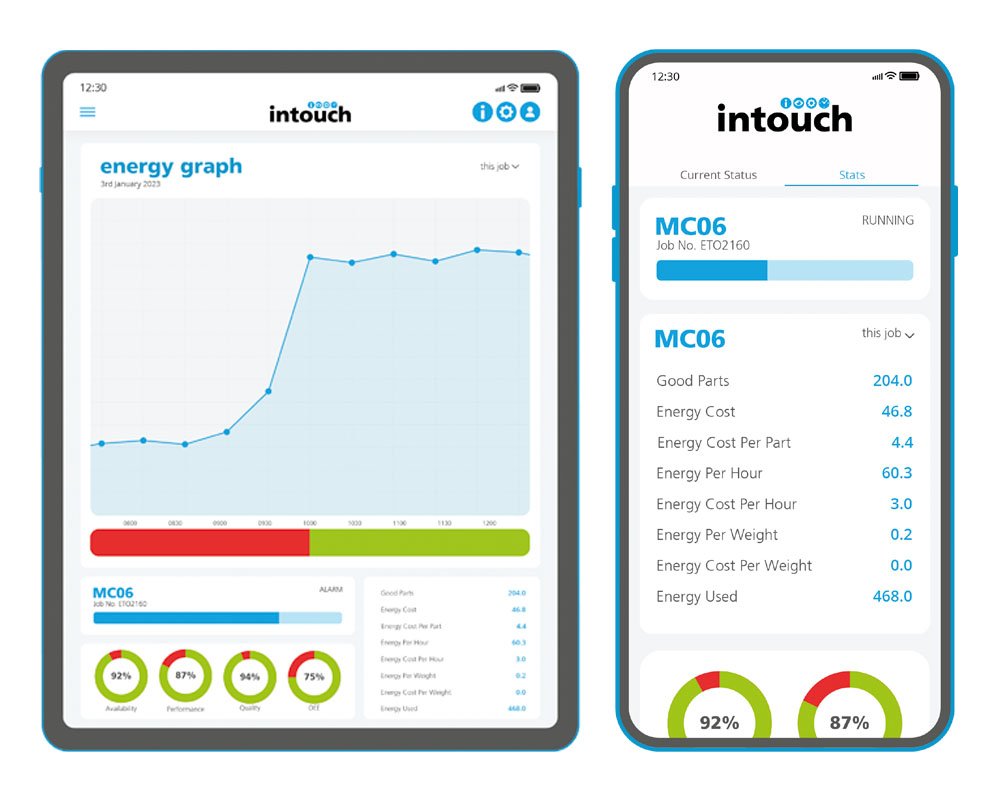

Intouch Monitoring, a pioneering leader in Production Monitoring Software announces their impressive new energy waste alert and energy monitoring software

Smart, digital manufacturing is the new operating standard worldwide and with their new module, manufacturers can achieve world-class energy-efficient production. At present, all manufacturers want to improve efficiencies and reduce their energy consumption, and Intouch’s new module will enable organisations to achieve this.

Up to 97% of a machines’ energy usage can be wasted while it’s idle, which is a significant loss of money and resources. Energy monitoring is the process of tracking, recording and visualising energy consumption in real time across an entire facility, and getting a comprehensive overview of each line or asset for optimised performance.

Energy monitoring alone does not reduce energy consumption, but having access to critical data, manufacturers can optimise consumption, address problem areas, change behaviour and drive down costs and emissions.

John Hardwick, Managing Director at Intouch Monitoring says:

'We are very excited about our new Energy Waste Alert module. We've been working together with our clients to refine the functionality and user experience. The goal is to ensure that the energy being used is put into making product and not just burning money!'

'Our new module gives much needed immediate notification of energy waste situations, which will deliver instant savings. If a hydraulic injection moulding machine stops but the motor is left on, it could still use over 50% of what it uses when running. We've made the new energy monitoring module an affordable addition to Intouch's production monitoring system, at just £5 per machine per month.'

For over 25 years, Intouch has remained focused on delivering easy to operate, easy to learn, quick to install, flexible and affordable Production Monitoring software, which has been fully supported by outstanding customer service and training.

It enables manufacturers to maximise efficiency and increase profitability with real-time production monitoring and MES, giving full visibility, in real-time.

The new energy monitoring module is an affordable addition to Intouch’s production monitoring system, at just £5 per machine per month.

Intouch puts production under the spotlight, allowing manufacturers to reach peak efficiency and profitability.

About Intouch Monitoring

Since 1997, Intouch has been finding straightforward, cost-effective solutions to the most common problems facing manufacturers. With over 25 years’ experience, we know it’s not a one-size-fits-all. That’s why customer service is at the heart of what we do. We pride ourselves on taking the time to understand your needs and tailoring our solution and training so that you get the most out of our system.

Intouch has now been installed in over 300 sites worldwide, transforming the production process for businesses in a wide range of industries. Through real-time monitoring and MES solutions, full visibility and control of operations is now easy – ‘Production monitoring software that’s your eyes and ears on the factory floor!’

great production performance made easy

For press enquiries

Contact: Nathan Clarke

Email: nclarke@intouchmonitoring.com

Phone: +44 1604 537100